Hi all,

For the last six months, I've been working on developing a high quality, high performance, all weather hop-up bucking and I am excited to share the outcome with you! I decided to start this project shortly after experimenting with a well known hop-up product known as the R-Hop

TM. In short, the R-Hop

TM delivers what it promises, i.e. improved accuracy and range. However, I and numerous others found the installation process to be quite difficult and time consuming requiring multiple patches to get one that works perfect for a first time user. The goal of this project was then to develop a product, completely from the ground up, that would offer equal to or better performance than the R-Hop

TM except in a drop-in solution.

The answer came in the form of the Tru-Hop

TM bucking. This hop-up bucking is installed like any other hop-up bucking on the market and requires 0 modification for its use. It significantly boosts range and accuracy for reasons I will describe below shortly. Additionally, this bucking will give consistent high performance results in a very wide temperature range (-50°C to 230°C). This means that you can expect the same range and accuracy regardless if you are playing in cold snow or out in a hot desert environment. Lastly, the material used in this hop-up bucking was chosen from an extensive list of options and was identified as the best choice due to multiple physical properties. One of which is the very high durability that allows the Tru-Hop

TM to withstand hundreds of thousands of rounds.

The secret to the aforementioned performance boost lies with the concave contact patch inside of the Tru-Hop

TM bucking. This contact patch was actually designed from scratch and then tuned through numerous redesigns and experiments. The end result is a shape that maximizes performance and is backed by hours of testing. One of the design goals of the internal contact patch was to maximize the amount of surface area that contacts the BB. This design has two main advantages. The first advantage comes from the increased amount of friction over the top of the BB due to a larger amount of material making contact with the surface. This friction allows the user to over-hop virtually any weight BB with minimal pressure from the hop-up arm. The second advantage is related to the first and will be more pronounced in a typical AEG. What happens here is that there is very little loss in muzzle FPS from increasing the hop-up. In other words, you can set your hop-up to the optimum setting for your desired flight path and still retain the full muzzle energy you get at 0 hop-up. The loss in FPS an average AEG typically experiences with increasing hop-up pressure comes from the stock bucking nub temporarily retaining the BB while air pressure is built up during firing. During this time, some air is leaked at the bucking-nozzle interface which leads to less kinetic energy at ideal hop-up. In contrast, the Tru-Hop

TM bucking allows the BB to pass more freely during firing since little hop-up pressure is required. The air losses at the nozzle-bucking interface are therefore reduced and thus more energy is retained during firing. This all translates to farther range at your optimal flight path.

The second major design goal of the concave contact patch was to boost the accuracy of the airsoft gun. I noticed that the shape of the concave patch changes as hop-up is applied. The final design had to compensate for this change in shape so that proper concavity can be maintained at the optimal hop-up setting. Hours of trial-and-error testing was put into tuning this feature alone so that the compatibility of the bucking was maximized across numerous BB brands. Other features of the bucking were thoroughly studied as well, but I won't go into details here. Simply put, every aspect of this bucking has been designed and tested to yield the maximum amount of performance from an airsoft gun.

I've also decided to go a bit beyond the bucking and designed a companion hop-up spacer that would replace the stock rubber cylinder in a typical hop-up unit. Although this spacer is not a requirement, I have found that additional precision can be squeezed out of your hop-up unit when used in conjunction with the Tru-Hop

TM bucking. Like the bucking itself, this spacer was also designed from scratch and then fine tuned for performance through trial-and-error and multiple redesigns. The end result is a product that can stand out by itself as an individual contributor to performance.

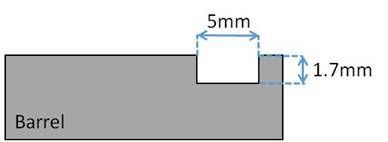

Due to the internal shape of the contact patch, there are some barrel requirements that must be met. This bucking was designed to be compatible across a large spectrum of barrel brands. However not all barrels will be compatible. To check for compatibility, one must only ensure that the barrel window meets the minimum dimensions shown below. Ideally the corners of the barrel window should be squared, however my team and I have tested rounded corners with success.

Well I tried my best to keep this post short and sweet, so please feel free to ask questions if anything is unclear. I hope you are as excited for this project as I am and thank you for reading through!